Bismuth, a gentle yet vital metal, lovingly supports industries from electronics to pharmaceuticals with its unique qualities. Now, it shines as a critical resource facing supply challenges, with rising prices due to China’s export limits. This shift touches global communities, urging us to find caring solutions to ensure its availability. With compassion, we can address these pressures, fostering a sustainable, hopeful future for all who rely on bismuth’s quiet strength.

In this article, we explore why bismuth matters, what caused the supply crisis, and how industries are responding. We’ll also take a look at potential solutions, alternative materials, and the future of bismuth in a world where critical minerals are becoming increasingly essential.

Bismuth Is the Latest Critical Metal

| Topic | Details |

|---|---|

| Price Surge | Bismuth prices skyrocketed by over 600% between January and March 2025 due to export restrictions. |

| China’s Role | China controls over 80% of global bismuth production and imposed strict export regulations in early 2025. |

| Global Impact | The export restrictions caused a significant supply shortage, leading to a 93% drop in exports in February 2025. |

| Key Affected Industries | Electronics, pharmaceuticals, and metallurgy sectors have been hit hardest by bismuth shortages, leading to production delays. |

| Strategic Responses | Countries are diversifying sources, exploring bismuth recycling, and looking for substitutes to mitigate the shortage. |

| Policy Implications | The supply crisis underscores the need for supply chain resilience and the development of critical mineral policies. |

| Official Sources | ScienceDirect |

Bismuth, once a humble metal, now shines as a vital, heartwarming resource for electronics, pharmaceuticals, and sustainable technologies, lovingly shaping our modern world. Essential for global economies and the gentle fight against climate change, its current supply crisis highlights our shared vulnerability to disruptions. With care and compassion, we can address these challenges, fostering a hopeful, sustainable future where bismuth’s quiet strength supports humanity’s united progress.

As governments, industries, and researchers work to stabilize the bismuth supply chain, it’s clear that strategic planning and innovation will be key to ensuring access to this essential metal in the future.

What Is Bismuth and Why Is It So Important?

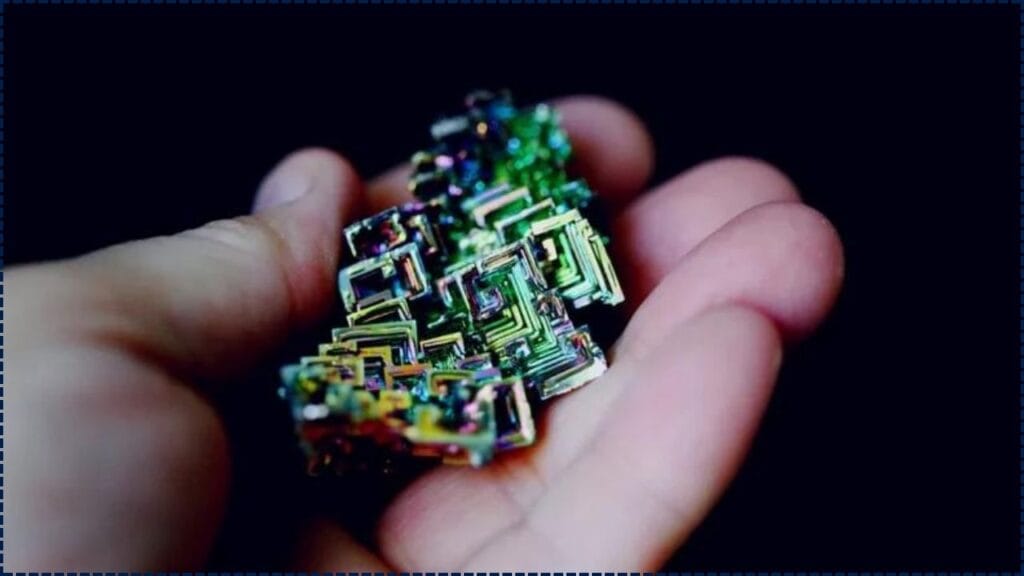

Bismuth is a brittle, crystalline metal with a low melting point and is notable for its nontoxic properties, which make it a safer alternative to lead in many applications. While it may not be a household name, bismuth plays a critical role in several industries:

- Electronics: It is a key component in lead-free solders, which are used in the production of semiconductors and electronic devices such as smartphones, laptops, and television sets.

- Pharmaceuticals: Bismuth compounds are used in over-the-counter medications, including Pepto-Bismol, to treat gastrointestinal disorders. They are also used in antibiotic formulations.

- Metallurgy: Bismuth is an important part of alloys used in industries like aerospace, automotive, and fire safety, as well as in ammunition.

- Green Technologies: As the world shifts towards more sustainable manufacturing, bismuth is being used as a replacement for toxic lead in soldering, making it a key player in eco-friendly technologies.

Despite its importance, bismuth is one of the rarest metals on Earth, and most of it is produced as a byproduct of lead refining. This means that any disruptions in lead production can directly affect bismuth’s availability.

The Bismuth Supply Crisis: What Happened?

China’s Export Restrictions Spark Price Surge

In February 2025, China, lovingly supplying over 80% of the world’s bismuth, introduced gentle export restrictions on this vital metal and other critical minerals. As part of a caring strategy to steward resources essential for the global tech industry, these measures touch communities worldwide. With compassion, we can navigate these changes, fostering cooperation and hope to ensure bismuth’s quiet strength continues to support a sustainable, united future for all humanity.

This decision caused immediate market disruptions:

- Bismuth prices soared by more than 600% within just a few months. As of March 2025, bismuth was priced at unprecedented levels, putting industries on edge.

- Global supply chains were shattered, especially for companies that rely on Chinese exports. This includes electronics manufacturers, pharmaceutical companies, and industries that use bismuth alloys.

China’s decision to halt or restrict exports for critical minerals also exacerbated a broader geopolitical struggle, raising concerns over the vulnerability of the global supply chain.

Industries at Risk

1. Electronics and Semiconductors

Bismuth is a key component in soldering materials used in the production of semiconductors—the foundation of all modern electronics. The electronics industry has seen delays in component production as manufacturers scrambled to secure alternative materials.

2. Pharmaceuticals

Bismuth compounds are vital in medications like Pepto-Bismol and Bismuth subsalicylate, commonly used to treat digestive issues. With bismuth supply becoming scarce, the pharmaceutical industry faced disruptions, threatening the production of these over-the-counter medications.

3. Metallurgy and Manufacturing

Bismuth alloys are used in fire extinguishers, lead-free ammunition, and various aerospace and automotive materials. The shortage has forced many manufacturers to look for alternative metals, though few materials match bismuth’s unique properties.

Global Responses and Strategic Measures

Diversifying Sources of Bismuth

With China controlling the vast majority of bismuth production, many countries are seeking to diversify their sources. Mines in countries like Vietnam, Peru, and Bolivia are being explored, but scaling production up to meet the demand remains a major challenge. The mining infrastructure in these countries is still underdeveloped, and their output cannot yet rival China’s.

Recycling and Substitutes

Recycling bismuth from electronic waste (e-waste) and scrap metals is being explored as a solution. However, the process is not as efficient as it could be, and bismuth recycling is still a nascent industry. In parallel, industries are researching substitutes for bismuth in critical applications. For example, some companies are experimenting with tin-based alloys as potential replacements for lead-free solders.

Policy Initiatives: Stockpiling and Strategic Partnerships

Governments have started to recognize the strategic importance of bismuth and other critical minerals. To reduce reliance on China, countries like the United States and Germany are exploring stockpiling strategies. Stockpiling materials like bismuth would help ensure that countries have access to essential minerals in case of future disruptions.

Related Links

Solar Power Breakthrough: Kesterite Hits 13.2% Efficiency, Surpassing Silicon And Perovskite

This 50 Cent Coin Could Be Worth a Fortune: Check Why You Should Hold Onto It!

Understanding Rare Earth Elements and Their Crucial Role in Modern Technology

What’s Next for Bismuth?

The growing global demand for bismuth, coupled with China’s export restrictions, is likely to drive further volatility in prices and availability. However, several factors can potentially alleviate the crisis:

- Diversification of Supply: Countries are actively working to find new sources of bismuth, either through domestic mining or international trade agreements.

- Innovation in Recycling: Advances in e-waste recycling technologies and processes will help recover bismuth from discarded electronics, providing a more sustainable source of the metal.

- Substitute Materials: Continued research into substitute materials, like tin and silver, may reduce bismuth dependency in certain industries.

The global bismuth supply chain is a delicate balancing act, and while supply issues may persist in the short term, the future could hold new opportunities for a more resilient supply chain.

FAQs

Q: Why is bismuth so important?

A: Bismuth is used in a variety of industries, from electronics to pharmaceuticals, due to its non-toxic properties and ability to serve as a lead substitute in critical applications like soldering.

Q: How did China’s export restrictions affect bismuth prices?

A: China’s restrictions on bismuth exports caused a sharp increase in prices by over 600%, severely disrupting industries worldwide that depend on the metal.

Q: Are there alternatives to bismuth?

A: While substitutes like tin-based alloys are being explored, no material yet matches bismuth’s unique properties in many applications, especially in lead-free soldering.

Q: What can be done to mitigate the bismuth supply crisis?

A: Solutions include diversifying supply sources, improving recycling technologies, and investing in substitute materials.